Products

Contact Us

Tel: +86-15831779588

Tel: +86-13473724675

Tel: +86-13731727729

Add:Da Chu Cun Hui Nationality Xiang Xingfu Avenue, Cang County, Cangzhou City, Hebei Province

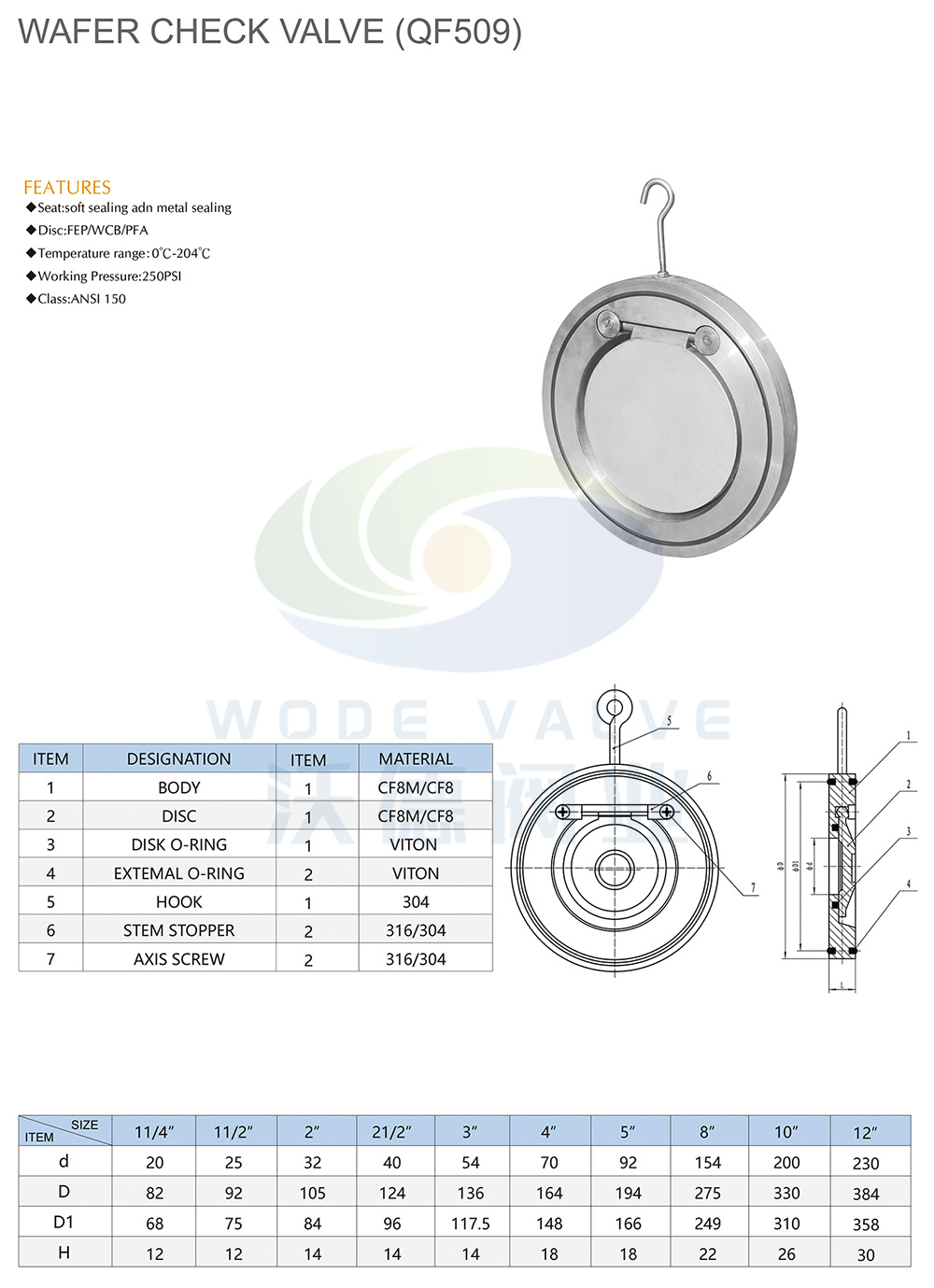

Wafer Check Valve (QF509)

- Commodity name: Wafer Check Valve (QF509)

- Product Description

-

How Wafer Check Valves Work:

Wafer check valves utilize a hinged disc mechanism that allows fluid flow in one direction. When the fluid flows in the desired direction, the pressure pushes the disc open, allowing the fluid to pass through. However, when there is a reverse flow or backpressure, the disc closes under gravity or spring action, preventing fluid from flowing backward.Compact Design and Easy Installation:

One of the key advantages of wafer check valves is their compact and lightweight design. Compared to other check valve types, such as swing check valves or lift check valves, wafer check valves require minimal space for installation. Their compact size allows for easy integration into piping systems, minimizing installation and maintenance costs.Versatility in Application:

Wafer check valves can be used in a wide range of industries and applications, including water and wastewater treatment, chemical processing, oil and gas, HVAC systems, and more. Due to their versatile nature, wafer check valves are suitable for both horizontal and vertical installations, offering flexibility in system design and operation.Efficient and Reliable Performance:

Wafer check valves are engineered to provide efficient and reliable performance. Their low-pressure drop design ensures minimal resistance to fluid flow, maximizing system efficiency. The sealing mechanism, whether rubber or metal, ensures tight closure and prevents leakage when the valve is closed, further enhancing reliability and safety.Durable Construction and Materials:

Wafer check valves are typically constructed from robust materials such as stainless steel, cast iron, or ductile iron. These materials offer excellent corrosion resistance, longevity, and durability, making them suitable for demanding operating conditions. Additionally, various sealing materials, such as EPDM or Viton, are used to ensure compatibility with different fluids and temperatures.Maintenance and Easy Access:

Maintaining wafer check valves is relatively simple due to their compact design. The wafer-style construction allows quick access for inspection, cleaning, or repairs without the need for dismantling the entire valve from the pipeline. This feature reduces downtime and facilitates routine maintenance tasks.

Company Profile

Wode Group was formed by four subsidiaries : Hebei Wode Valve Co., Ltd., Cangzhou Qunfeng Stainless Steel Products Co., Ltd., Hebei Wode Casting Co., Ltd. and Cangzhou Wode Mold Factory.

Hebei Wode Valve Co., Ltd is a company integrating product design and development, mold manufacturing, casting, finishing, finished product assembly and inspection. We has a building area of 20000 square meters. At present, we have more than 100 sets processing machines, including CNC lathes, machining centers, carving machines, ball processing machines and other equipments, 5 automatic ball valve assembly lines. 200 employees and 40 senior technicians formed a excellent team. Our valves annual output is 4 million sets.

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!